3m 4m 5m 6m 7m 8m 9m 10m 11m 12m stâlp cu braț simplu și dublu companie de stâlpi de iluminat stradal

Scurtă descriere

1. Înălțime: 3m-35m

2. Material: Oțel Q235/Q345/Q460

3. Tratamentul suprafeței: galvanizat la cald + acoperire cu pulbere

4. Grosimea stratului de zinc:>80

5. Garanție: 20 ani

descrierea produsului

Avantajul companiei:

Stâlpii lămpii sunt supuși unui proces de acoperire în două etape constând din galvanizare la cald și pulverizare electrostatică.

Procesul de galvanizare la cald urmează fie standardul chinez GB/T 13912-2002, fie standardul american ASTM A123 sau AS/NZS 4680:2006. Acest proces implică scufundarea stâlpilor într-o baie de zinc topit pentru a crea un strat protector de zinc. Alternativ, stâlpii pot fi vopsiți cu pulbere sau vopsiți în funcție de cerințele specifice ale clienților.

Procesul de acoperire include etapa crucială de pulverizare a plasticului, care este esențială pentru asigurarea proprietăților anticorozive ale stâlpilor. Pulberea profesională de înaltă calitate pentru exterior este utilizată pentru a se asigura că stâlpii lămpii își păstrează strălucirea și aspectul pe termen lung.

Flanșele stâlpilor lămpii sunt întărite pentru a le spori rezistența și stabilitatea, asigurându-se că pot rezista la diferite condiții meteorologice și forțe externe.

Sudarea stâlpilor lămpii este conformă cu standardul AWS D1.1. Se poate realiza fie prin sudare cu CO2, fie prin metode de sudare cu arc scufundat. Procesul de sudare asigură că nu există fisuri, cicatrici, suprapuneri, straturi sau alte defecte. Atât sudarea interioară, cât și cea externă contribuie la aspectul estetic general al formei stâlpului.

Placa de bază a stâlpului poate fi de formă pătrată, rotundă sau poligonală, în funcție de preferința clientului. Dispune de găuri cu fante pentru șuruburi de ancorare, permițând o instalare sigură. Dimensiunile plăcii de bază sunt personalizate în funcție de cerințele clientului.

Stâlpii lămpii sunt supuși galvanizării la cald, fie conform standardului chinez GB/T 13912-2002, fie conform standardului american ASTM A123 sau AS/NZS 4680:2006. În plus, acestea pot fi vopsite cu pulbere sau vopsite pentru a satisface preferințele specifice ale clienților. Aceste tratamente de suprafață sporesc și mai mult rezistența la coroziune și aspectul vizual al stâlpilor.

Parametrii produsului

| Înălţime | Sus/Jos (MM) | THK(MM) | Flanșă (MM) | De bază (MM) |

| 6M | 70/135 | 2.75 | 260*12 | 60 * 18 mm |

| 7M | 70/150 | 2.75 | 260*12 | 70 * 18 mm |

| 8M | 70/158 | 3 | 300*12 | 75 * 18 mm |

| 9M | 80/185 | 3.25 | 320*14 | 80 * 20 mm |

| 10M | 78/185 | 3.5 | 350*16 | 85 * 22 mm |

| 11M | 80/200 | 3.5 | 400*18 | 95 * 22 mm |

| 12M | 80/215 | 3.5 | 400*18 | 95 * 22 mm |

descrierea produsului

Portret corporatist

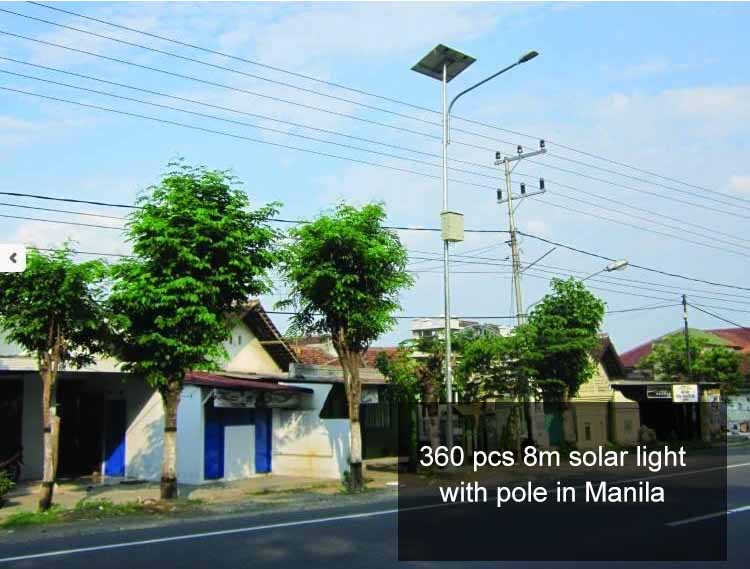

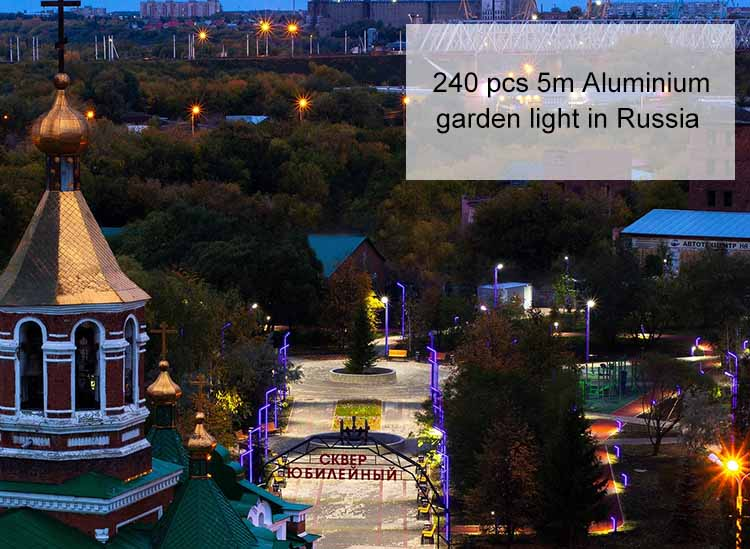

CAZUL PROIECTULUI

EN

EN